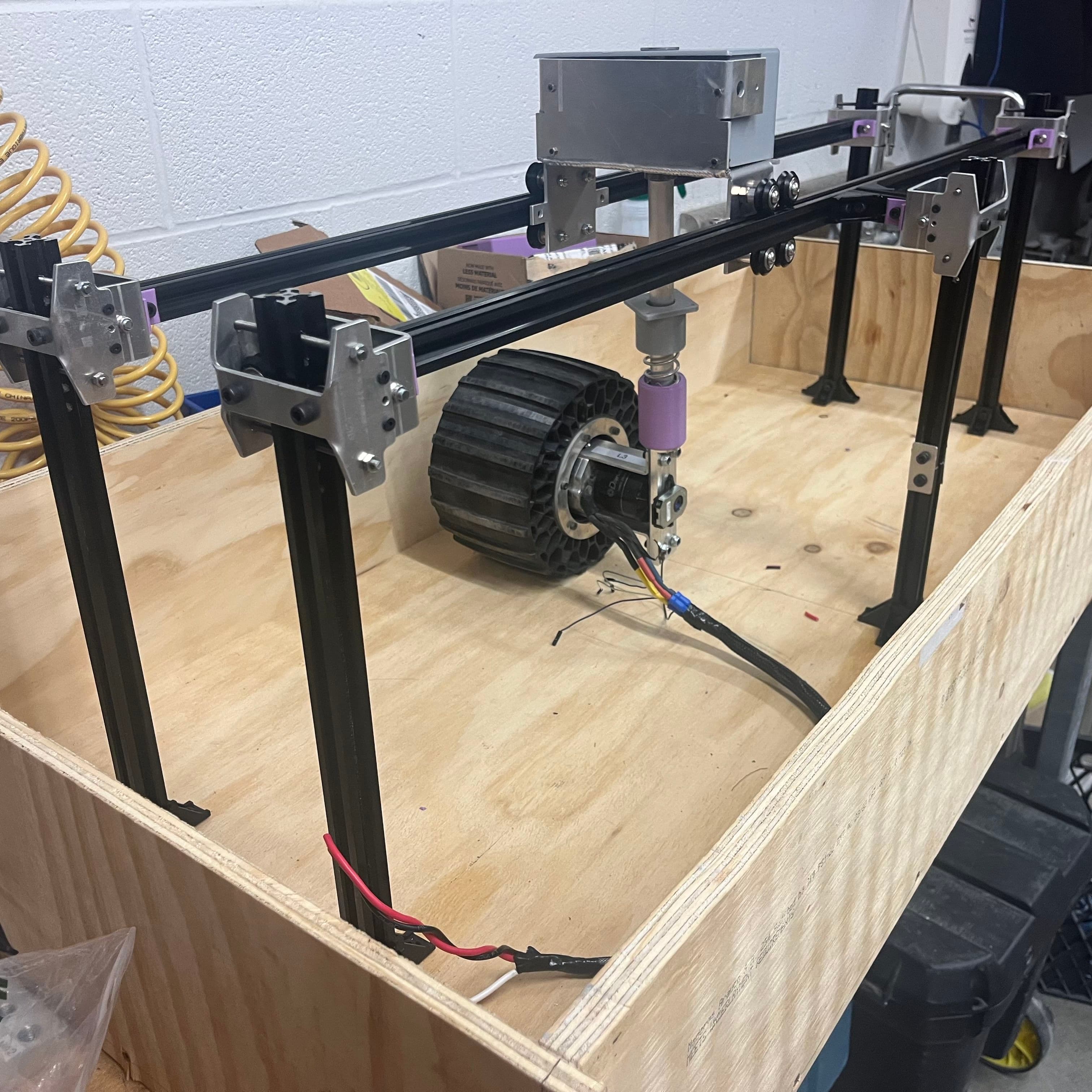

Wheel Test Jig

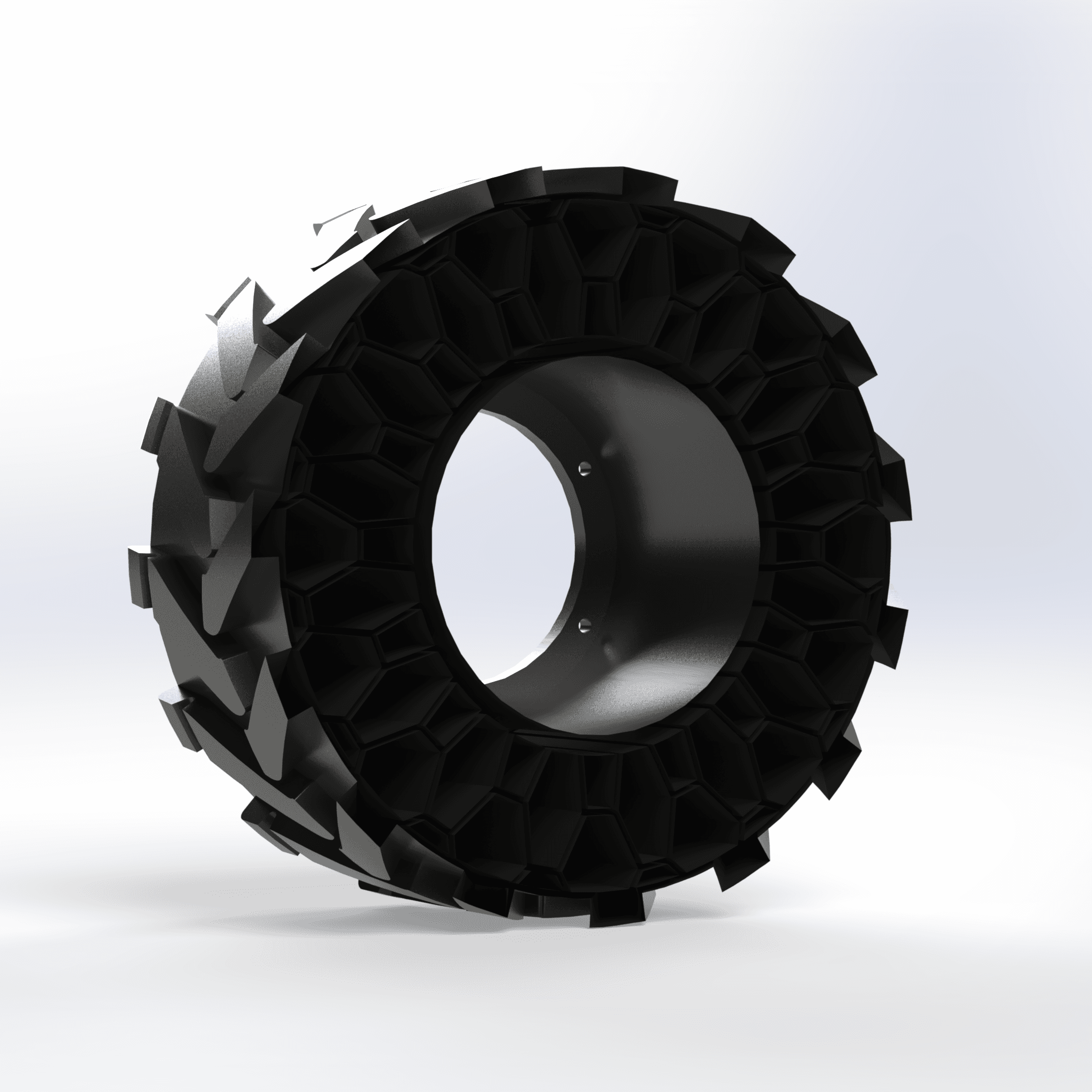

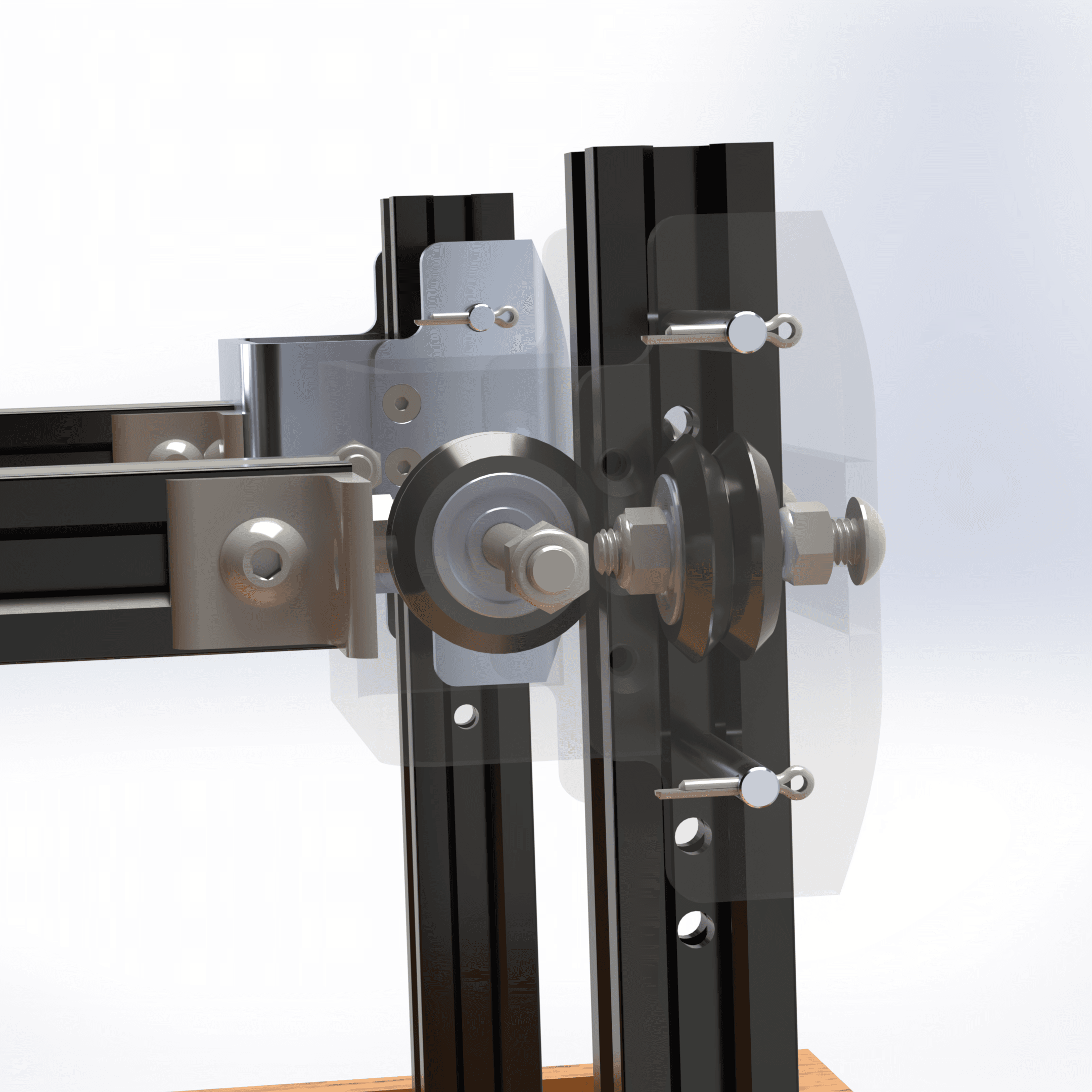

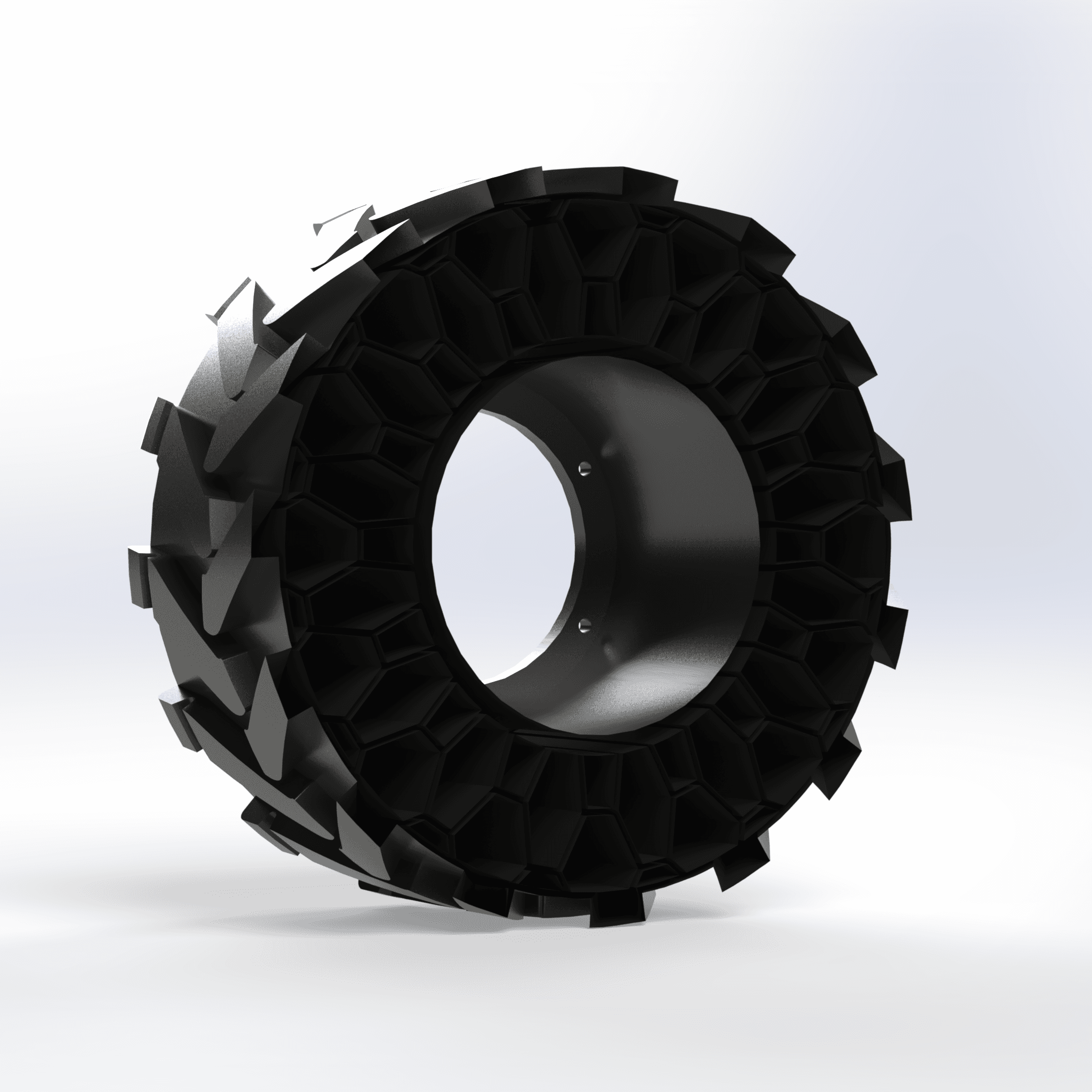

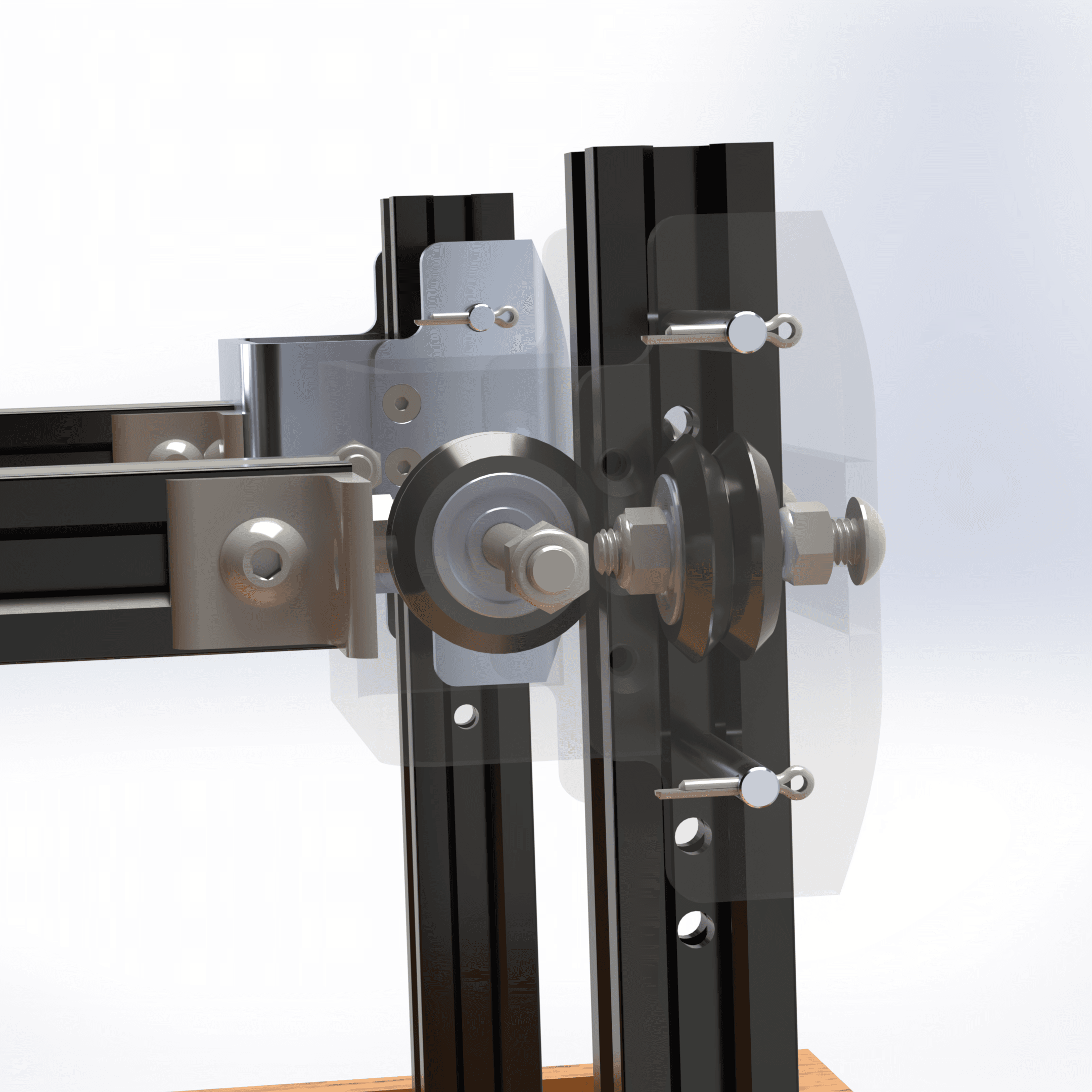

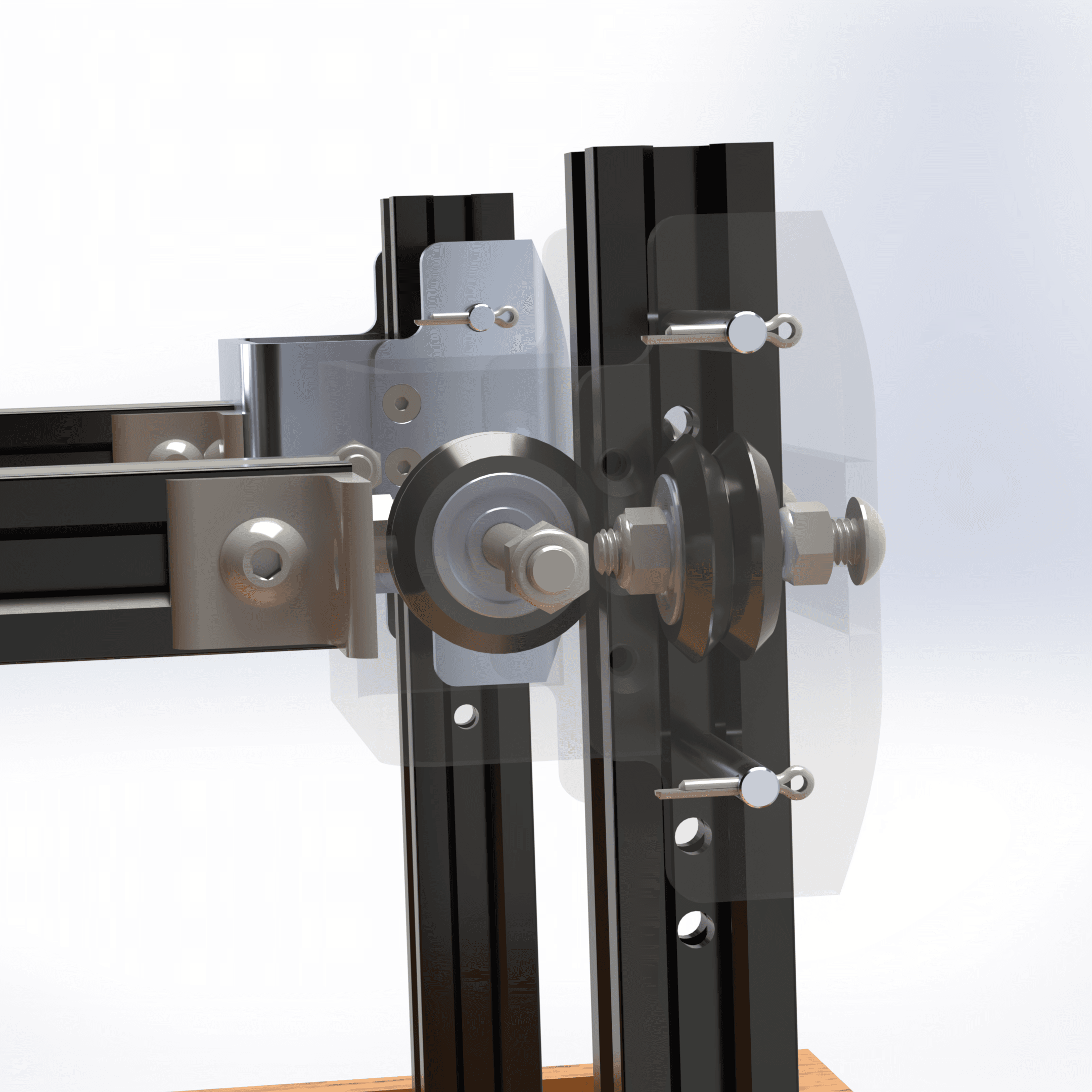

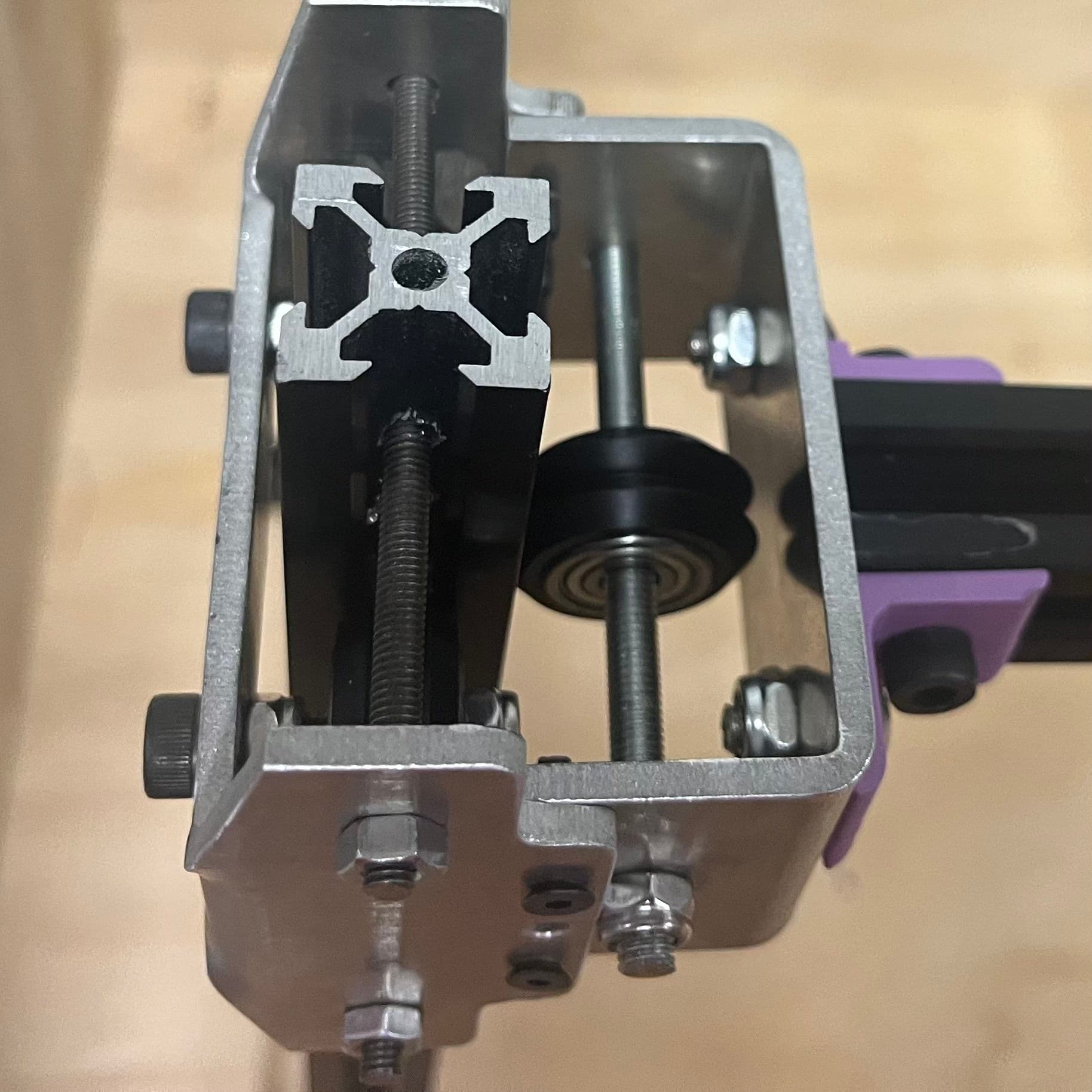

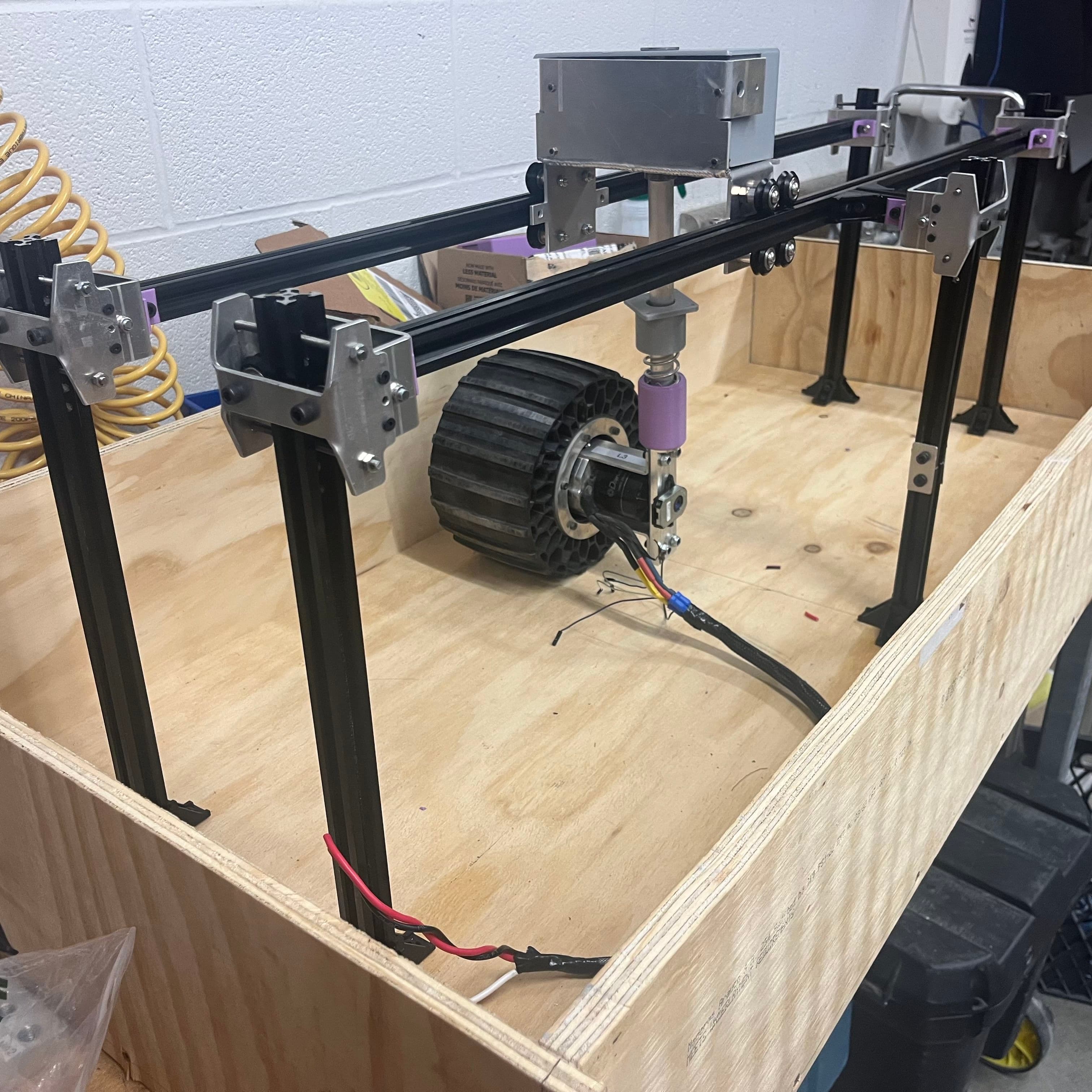

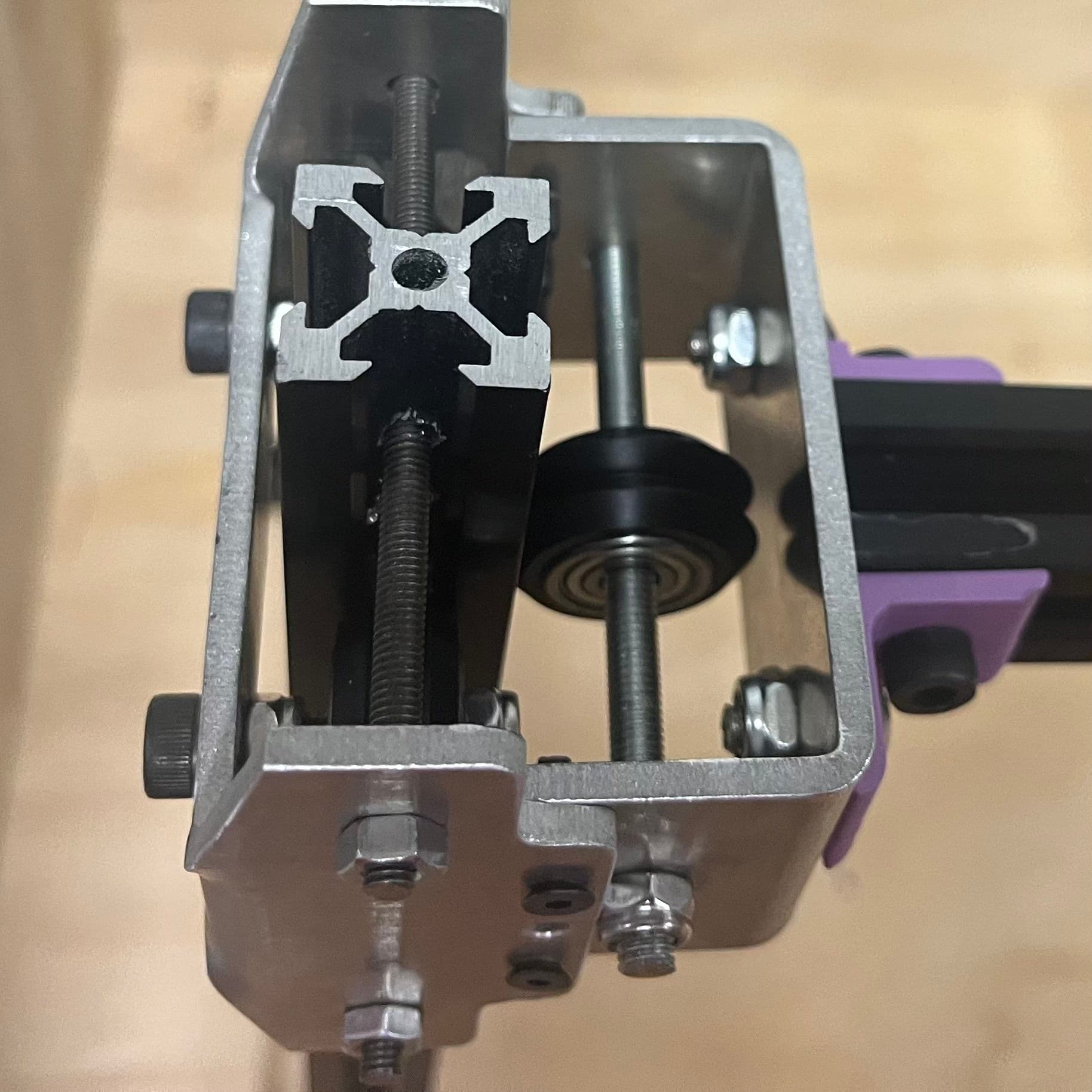

CAD Design

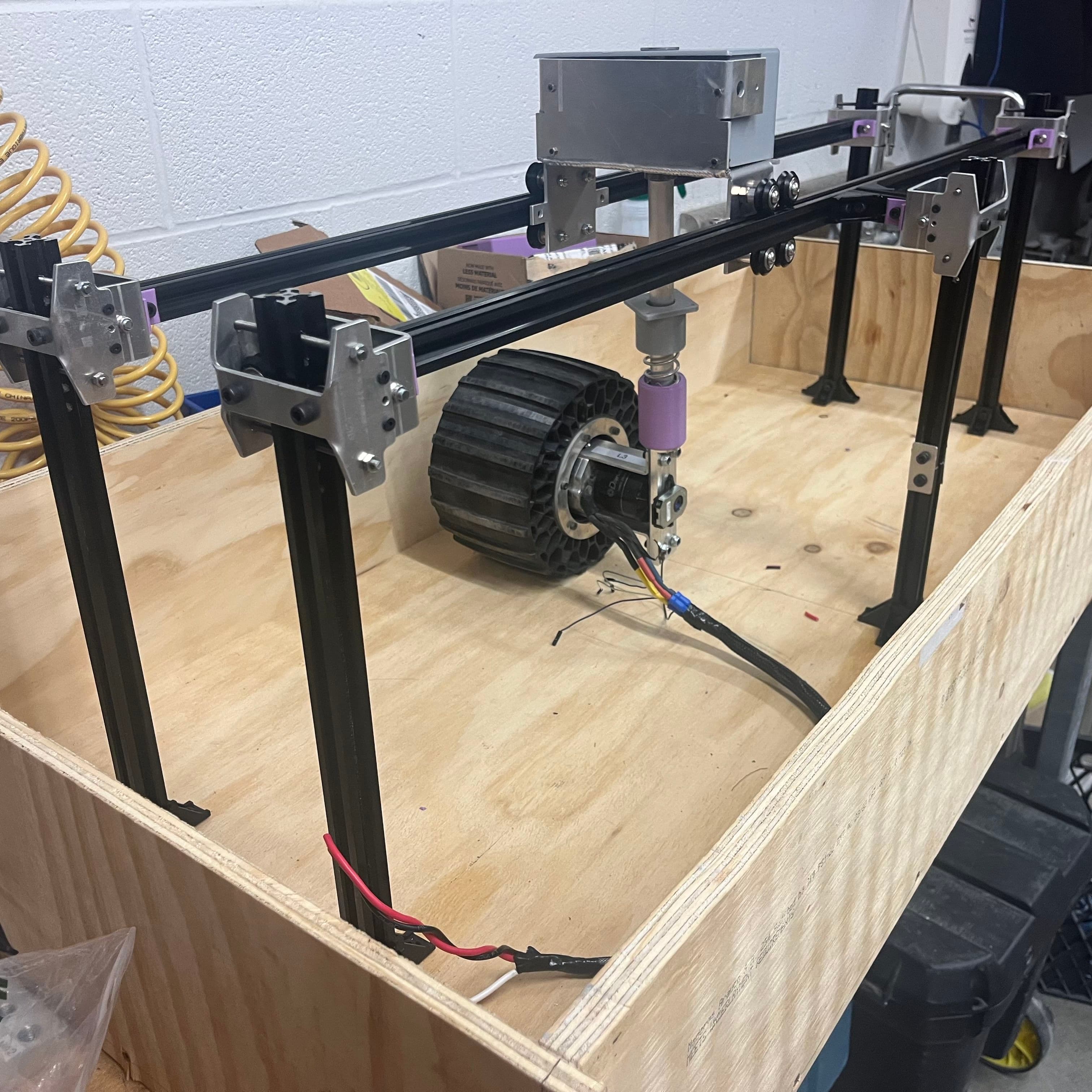

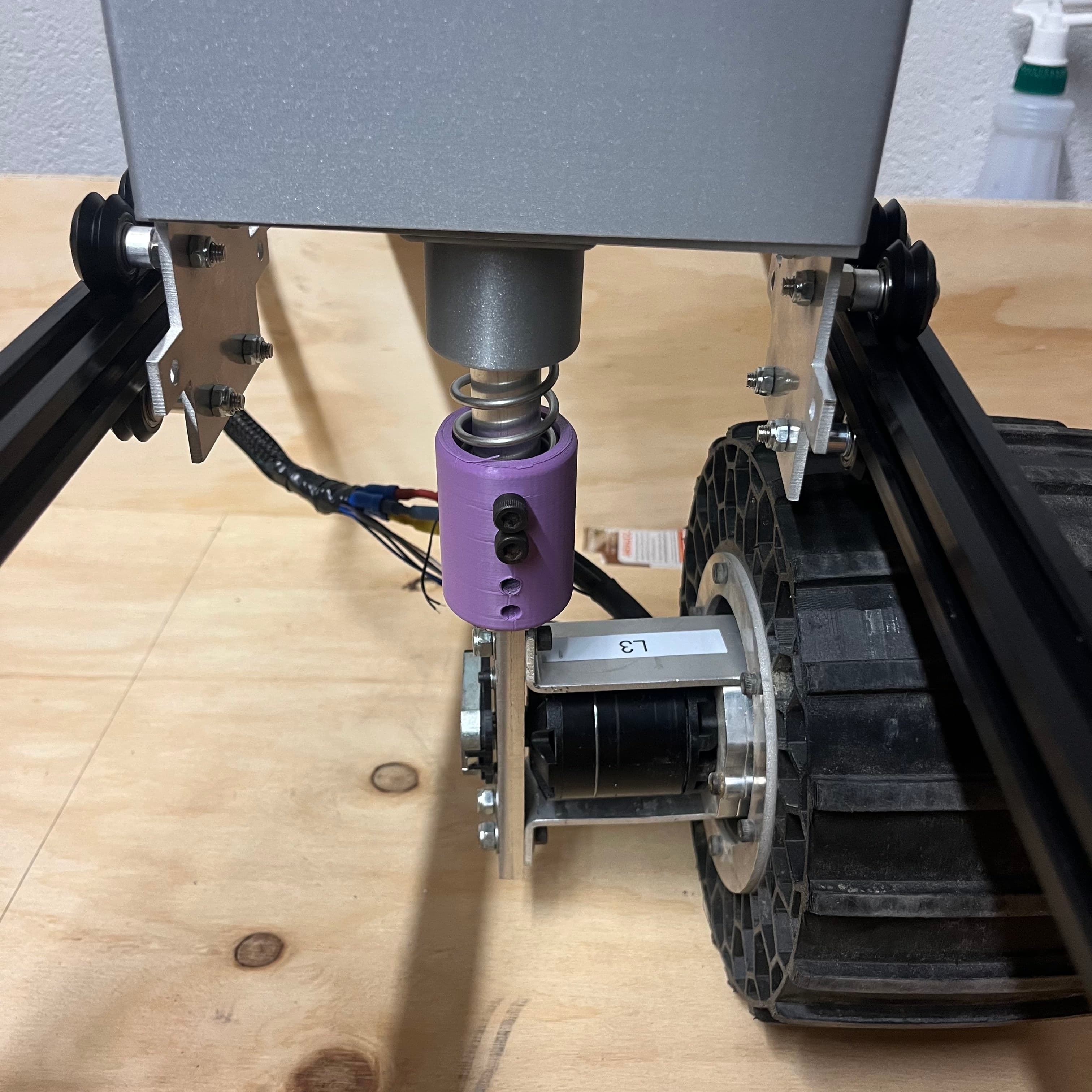

Current Progress

Objective

Design and assemble sub-30kg wheel test jig using sheet metal to mitigate wheel motor failure and optimize wheel geometry for the UW Mars Rover Team.

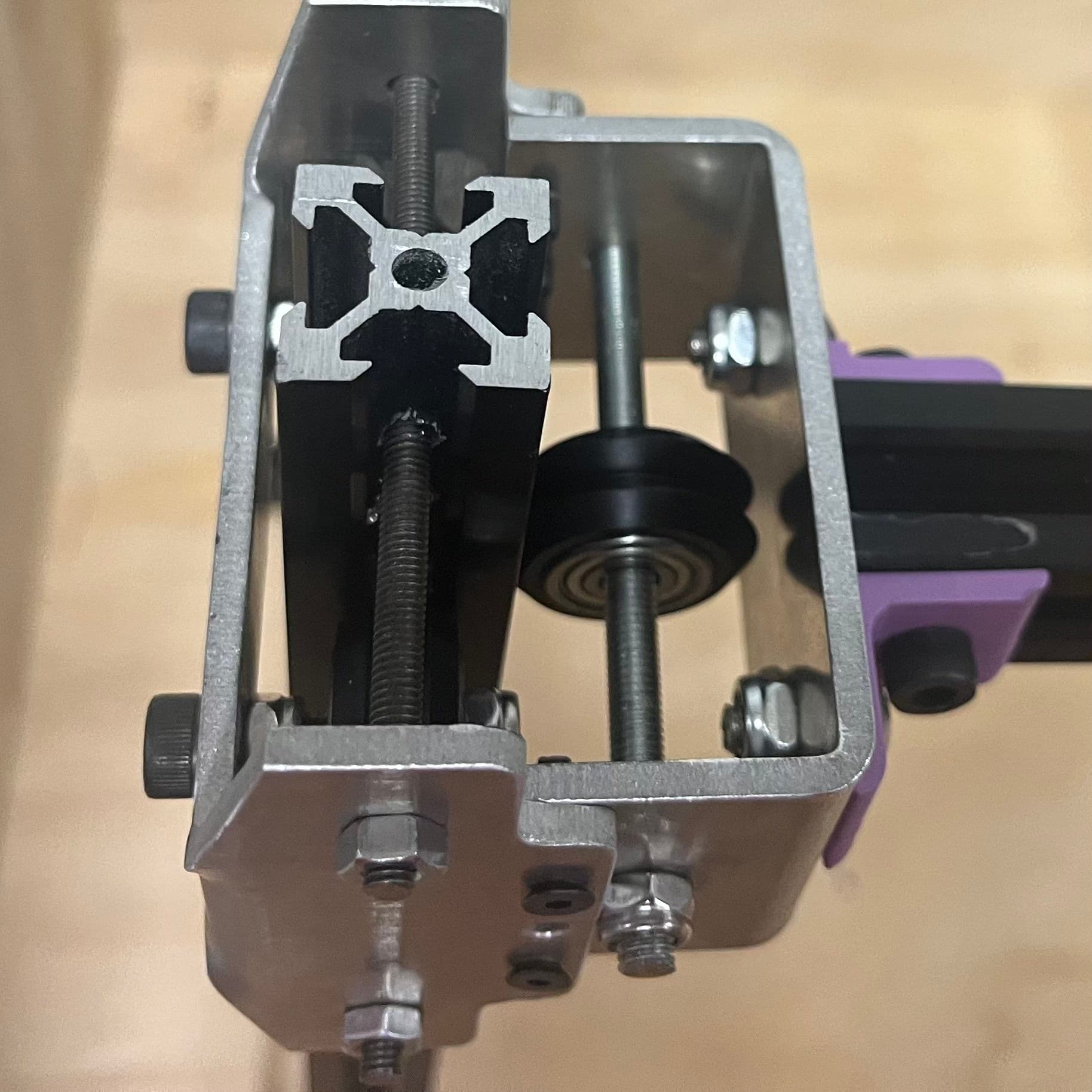

Process

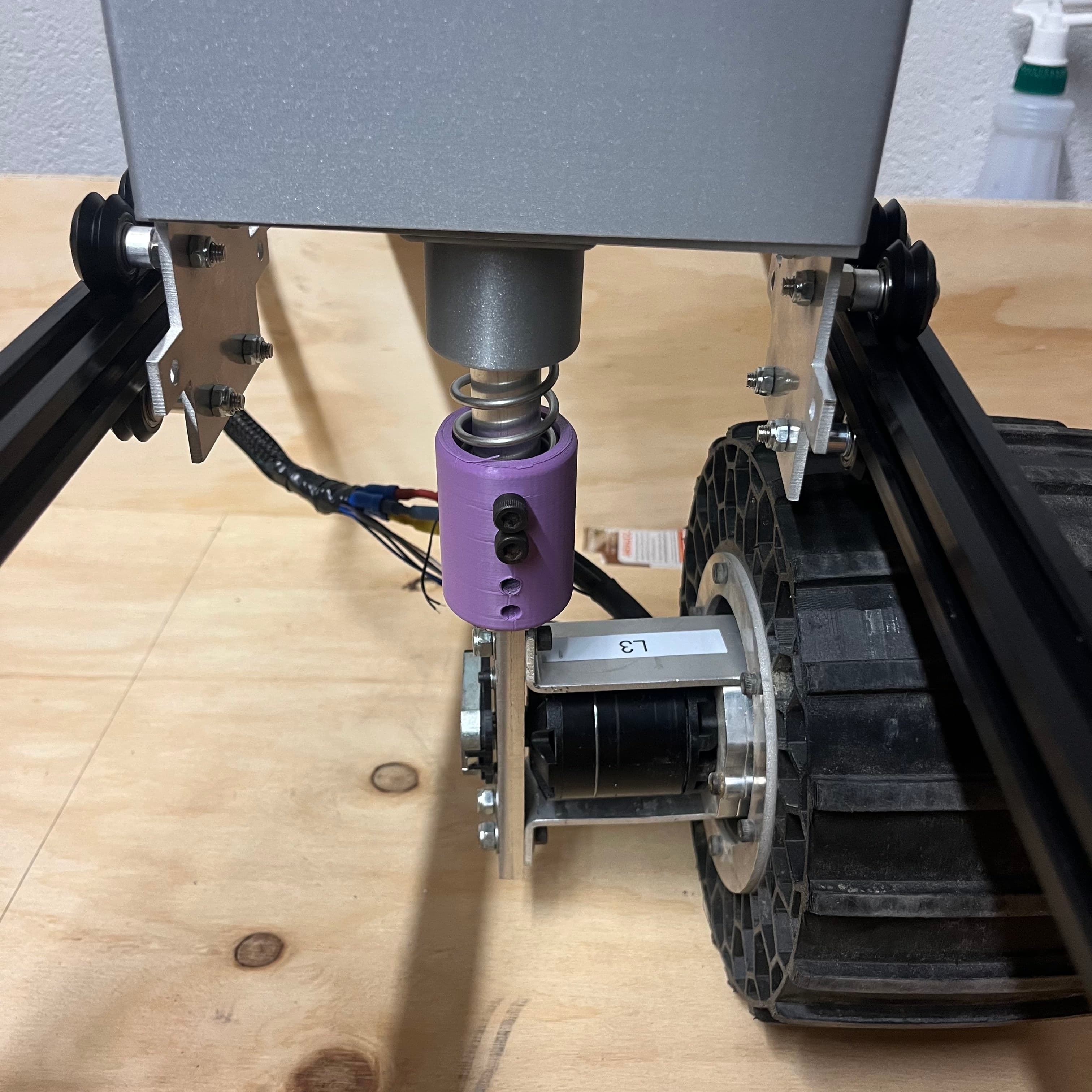

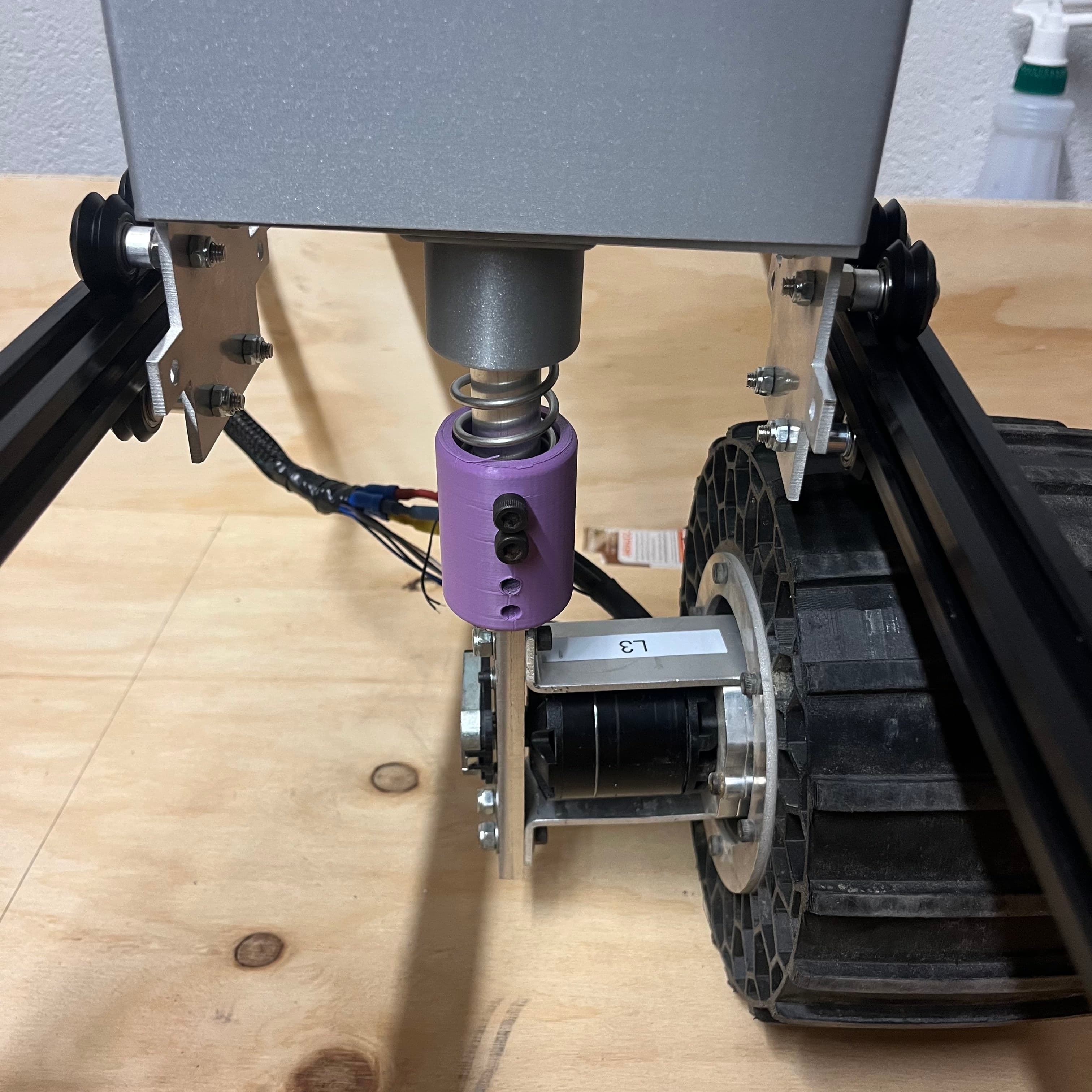

- Developed force simulation using compressed spring reaction force to approximate real-world wheel loading cases

- Developed a test plan targeting 5 specific failure modes

- Implemented motor current data collection using Python

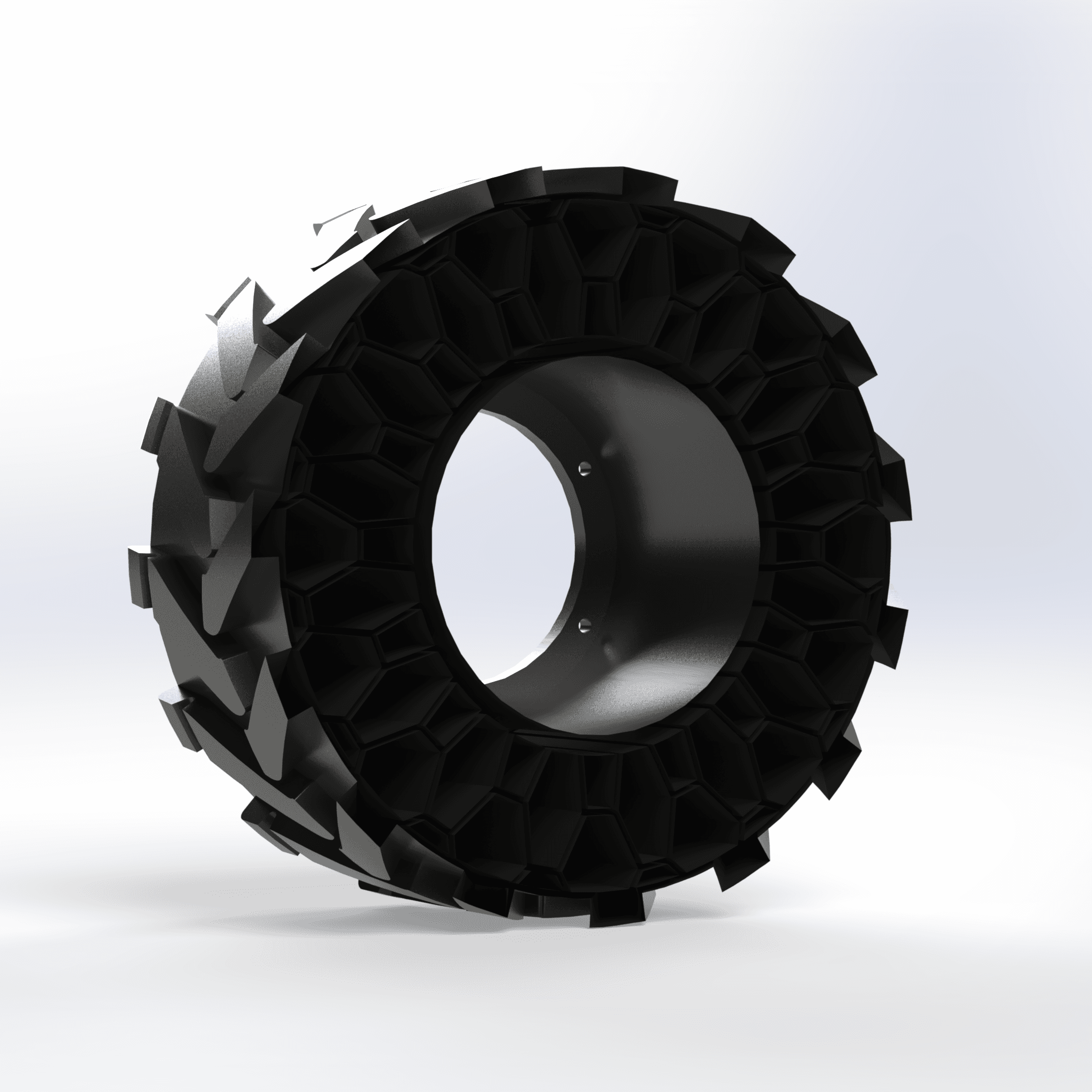

- Currently 3D printing new wheel for testing

- Skills used:

- SolidWorks (simulation and drawings)

- Sheet metal

- Woodworking (track saw cutting)

- Odrive for motor control

- Python for data collection

- Excel for data visualization

- Machine shop tools (mills, lathes)

- 3D printing

Anticipated Outcome

Projected to deliver a 25kg portable test platform capable of repeatable wheel performance evaluation in simulated sandy terrain, with integrated telemetry for failure analysis and design optimization.