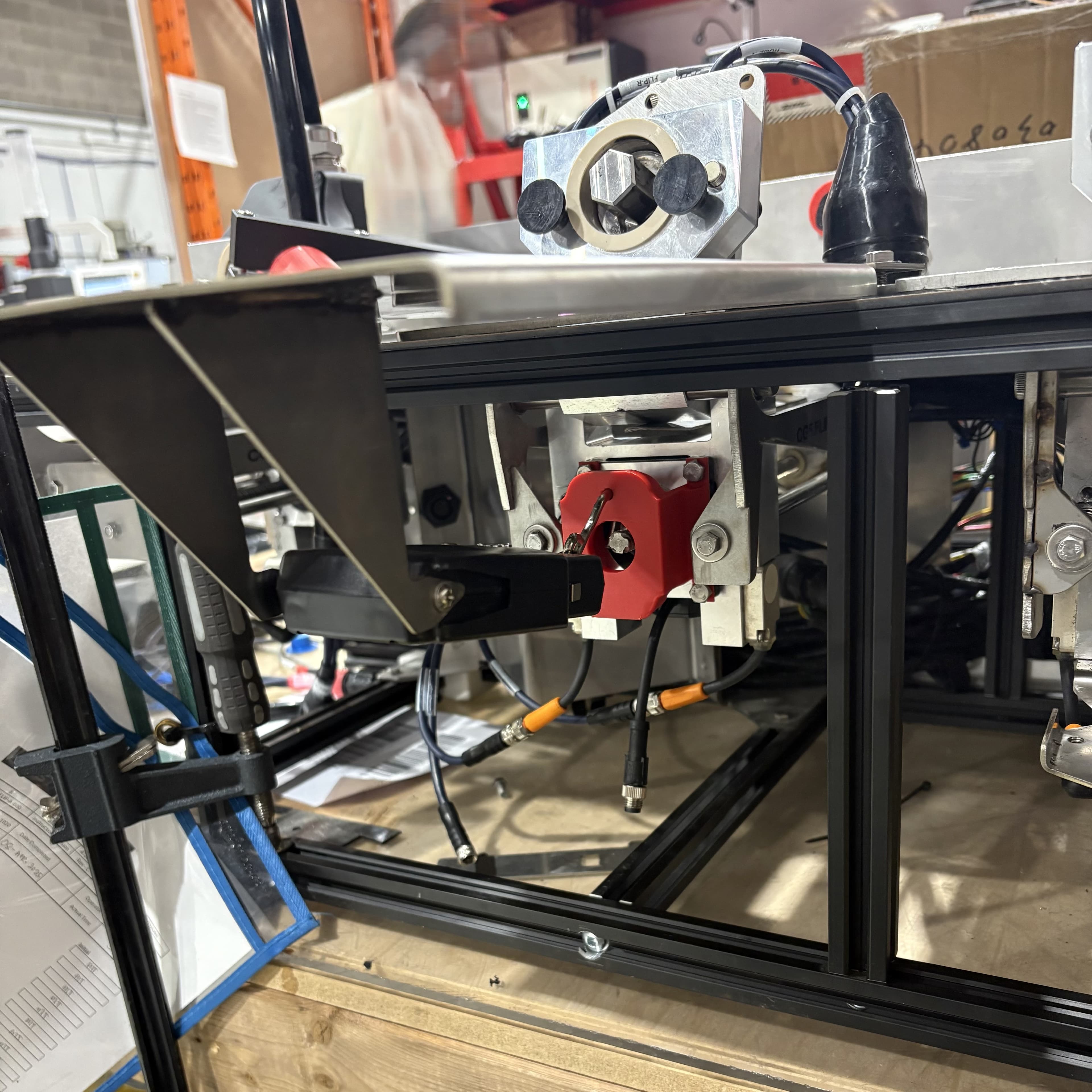

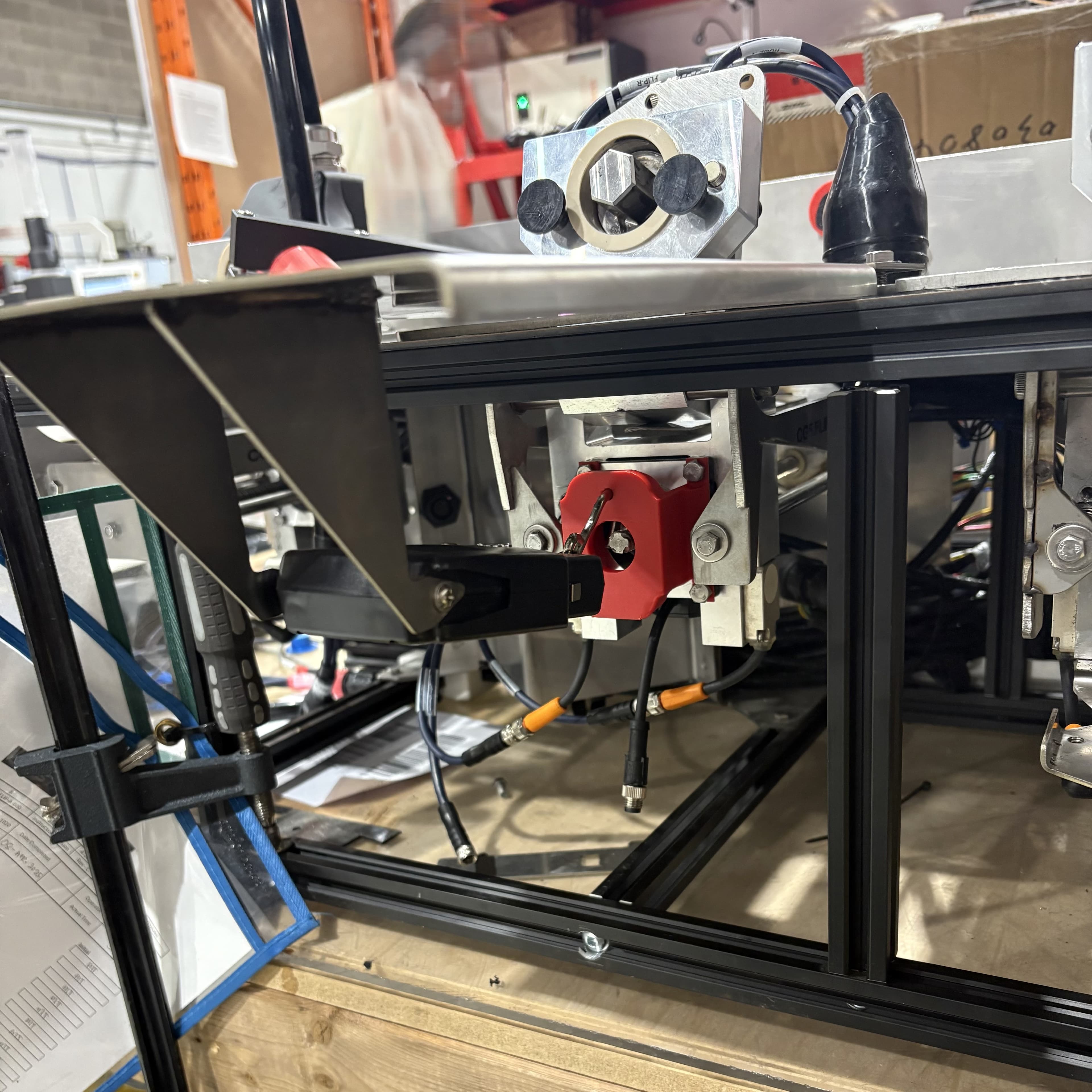

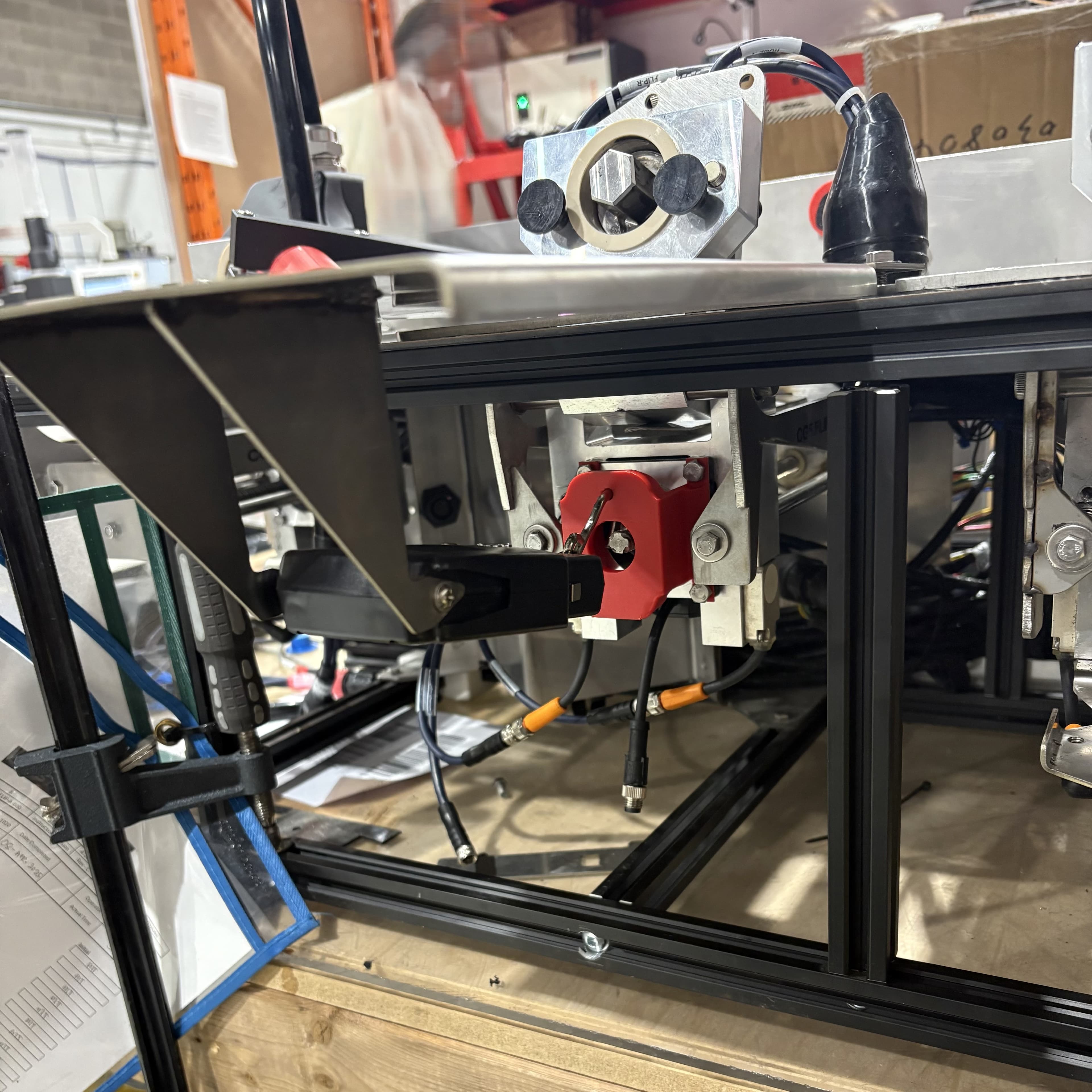

Motor Stall Force Test Fixture

Objective

Evaluate three coating types (DLC, TiN, Chrome) on SS304 lead screws and guide rods with 2-2.5μm coating thickness to quantify friction reduction to determine cost-benefit viability for production-scale coating implementation across all sub-mechanisms.

Process

- Developed linear actuator force measurement fixture:

- SolidWorks design

- Laser cut sheet metal

- Press brake forming

- Tack and filler welding to strengthen joints

- Comparing DLC, TiN, Chrome coatings vs uncoated SS304 baseline across polymer and bronze bushing combinations to identify lowest friction (motor current reduction), highest durability (extended runtime), and best grease resistance

- Established 9 quantitative metrics tracked with/without honey: rod diameter, bearing ID, initial/final linear force, motor current, run time to failure, motor temp, shaft temp

Result

Initial testing identified promising coating combinations with improved pull force. However, week-long stress testing revealed that the coatings peel off after 2 days due to the high friction, indicating that alternative material systems or design modifications are required.